Enterprise Quality Management Software (EQMS) is an answer that contacts various parts of the esteem chain—building, obtainment, fabricating, inventory network, deals, administration and that’s only the tip of the iceberg. Since progress for such a usage relies upon conveying both business esteem and consistency over a wide arrangement of partners, it tends to be an extraordinary test for some associations.

In the event that you are at present in charge of or are wanting to execute an EQMS arrangement sooner rather than later, the rundown of five stages beneath will enable you to maintain a strategic distance from traps and guarantee achievement.

Stage 1: Clearly Define Objectives

Understand the objectives and goals of the usage. It is vital that your targets incorporate both business advantages and consistence or cost shirking. Particularity is vital in characterizing business benefits. For instance, you may gauge the Cost of Quality (Cost of Good Quality + Cost of Poor Quality)and need to lessen it by X%, need your piece rate to be X% or just need X measure of item on hold in the distribution center dependent on interest and estimates. With consistency, destinations to handle ought to likewise be outlined in advance—CAPA process is broken or administrative entries are taking excessively long. The fact of the matter is to assess and gauge the present status, at that point set future objectives. It is additionally vital to comprehend necessities that are basic for your tasks—explicit usefulness, adaptability, interoperability, innovation stage, multi-dialect needs, etc.

Stage 2: Bring Together a Cross

Functional Team Sponsored by Executives – The group ought to be supported by an innovator in the organization, for example, the VP of Operations, COO, Chief Risk Officer, and so on. It ought to likewise include different jobs along the esteem chain, including quality and IT administrators, representatives from various lines of business, officials and outsider specialists. Since this is a venture level activity, official purchase in and bolster from utilitarian groups are fundamental for a smooth EQMS usage.

Stage 3: Focus on Speed to Value

Months and, sometimes, years can without much of a stretch go for programming usage to be finished. Center ought to associate with how rapidly you can demonstrate an incentive through the usage without affecting long haul targets. In the event that it’s taking over a year to get the product running, it’s taking excessively long. Begin with only a solitary or a couple of procedures or capacities, assemble them out and afterward expand. NC/CAPA or Supplier Quality are extraordinary instances of beginning stages.

Stage 4: Take a Risk-Based Approach

Although it’s not in every case ostensibly obvious, all that we do in Quality Management is tied in with lessening hazard. SOPs, HACCP, NC/CAPA, GMP—they all diminish hazard. Sadly, numerous organizations center around these individual parts, yet don’t unite them for a comprehension of the full hazard portfolio. By applying the Risk Management Framework—survey, evaluate, organize, relieve—the genuine estimation of your quality activity can be seen, regardless of whether antagonistic occasions never happen. Ensure you manufacture an incorporated procedure for hazard the executives inside the EQMS framework, binds quality to chance at a venture level. This will enable separate to storehouses and increment perceivability among offices and procedures.

Stage 5: Calculate ROI

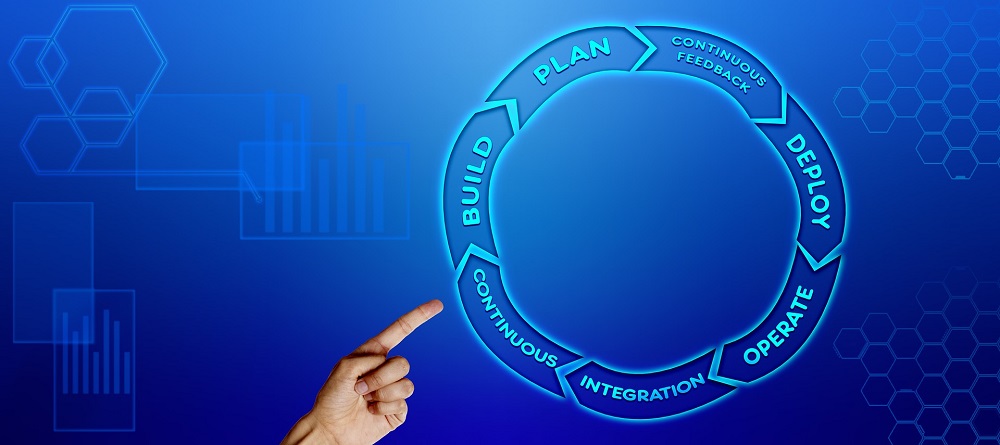

The money related venture and measure of assets utilized are extremely incredible to not quantify the effect your quality administration procedure is having on the business. Sadly, numerous organizations measure and conjecture the advantages of new programming preceding its usage, at that point dismiss assessing if and how well it’s functioning. It is basic for long haul accomplishment to compute ROI to quantify ventures with respect to desires. This empowers ceaseless enhancement and keeps the cycle pushing ahead.

Adopting a developing EQMS advances isn’t just a method for modernizing your assembling association, it’s basic to remain focused. The focal points, to give some examples, of expanded straightforwardness, institutionalization, increased information trustworthiness, robotized consistence, CAPA methods and factual slanting apparatuses specifically mean operational efficiencies that influence the primary concern. Following the above advances will encourage a fruitful usage and will enable your association to drive operational and business esteem.